Customer-Focused Injection Molding

J&L Plastic Molding’s capabilities are aligned with the Quality & Quantity requirements of our injection molding customers!

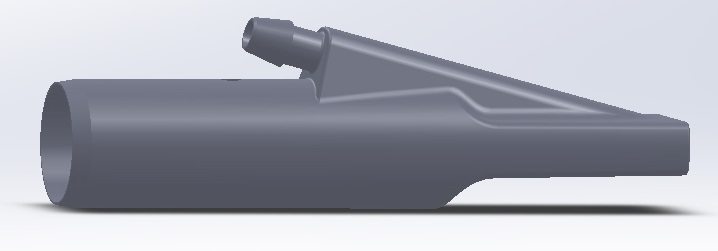

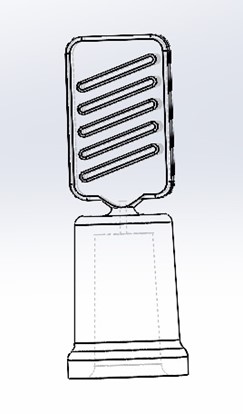

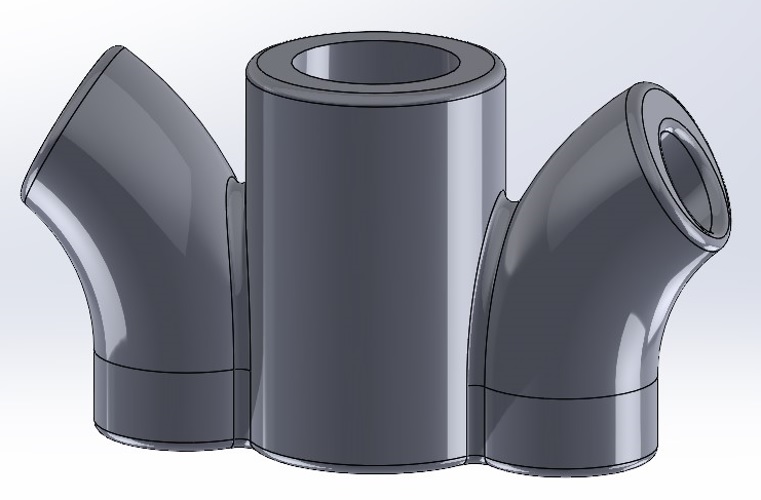

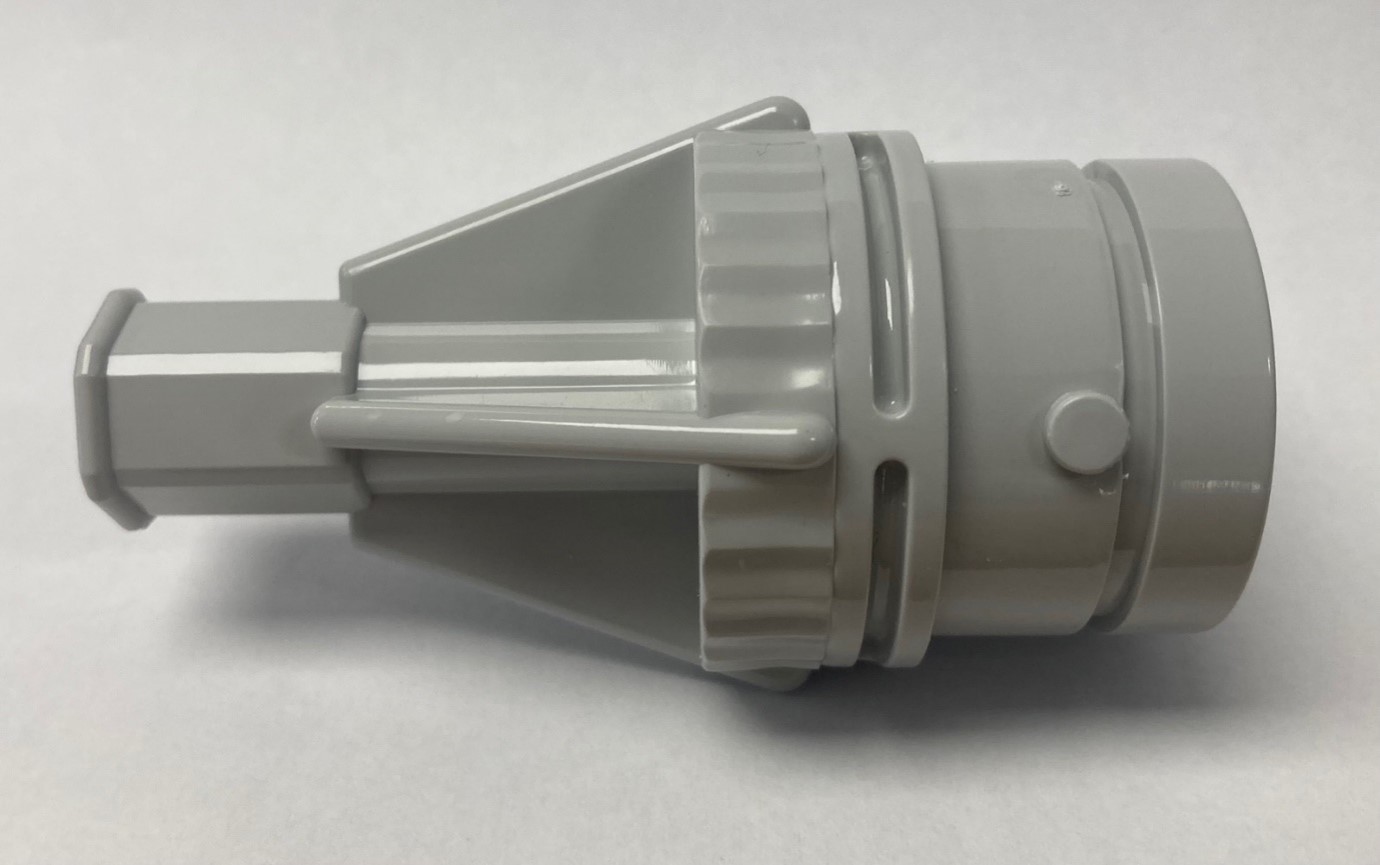

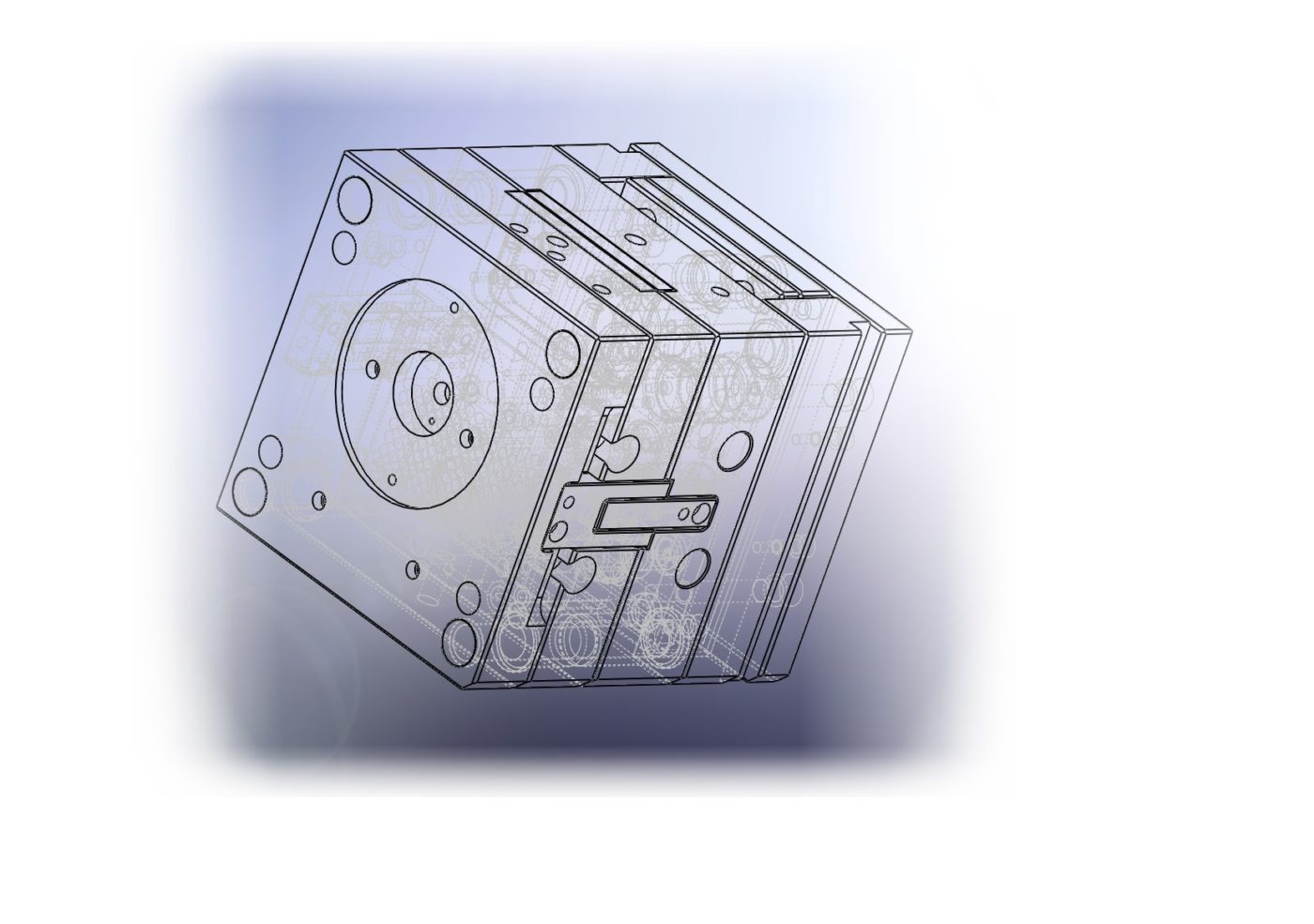

A successful injection molding project must meet the requirements of your part design, tolerancing, material selection, quantity demand and timing needs. These requirements steer J&L Plastic Molding’s quoting process to find the proper solution. We select the appropriate tooling frame system and steel to meet the demands of your specified type and grade of material, part design, tool life expectation and demand quantity.

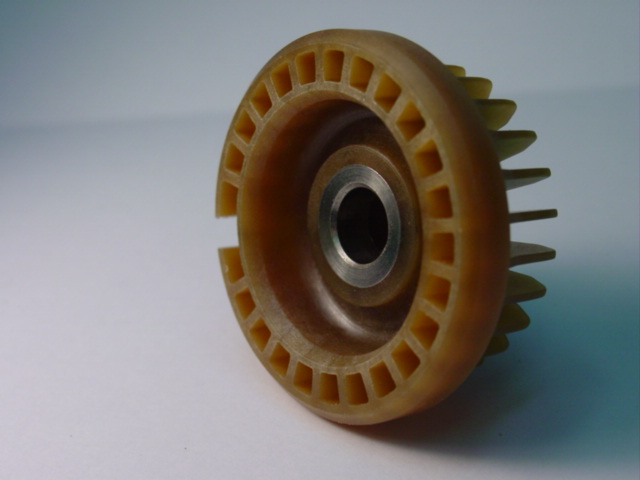

J&L is an ISO 13485:2016 certified moldmaker and injection molder with vast experience in medical device and other industries. We specialize in processing highly engineered materials with high performing mechanical and thermal properties. We produce parts that perform in demanding conditions and harsh environments.

The common thread through a J&L tooling and molding project is meeting our customers’ quality demands with on-time delivery of required parts.

Have a Question? Click HERE to Email us

How We Do It

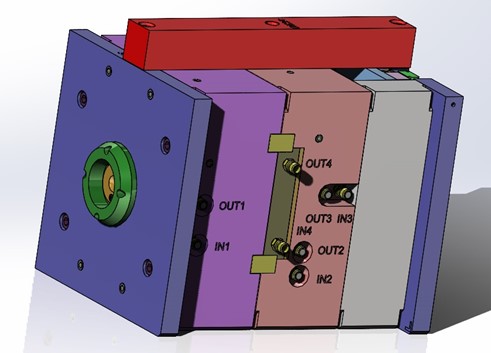

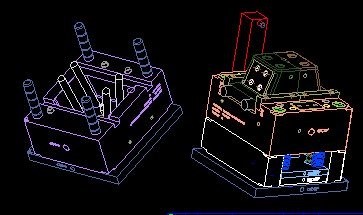

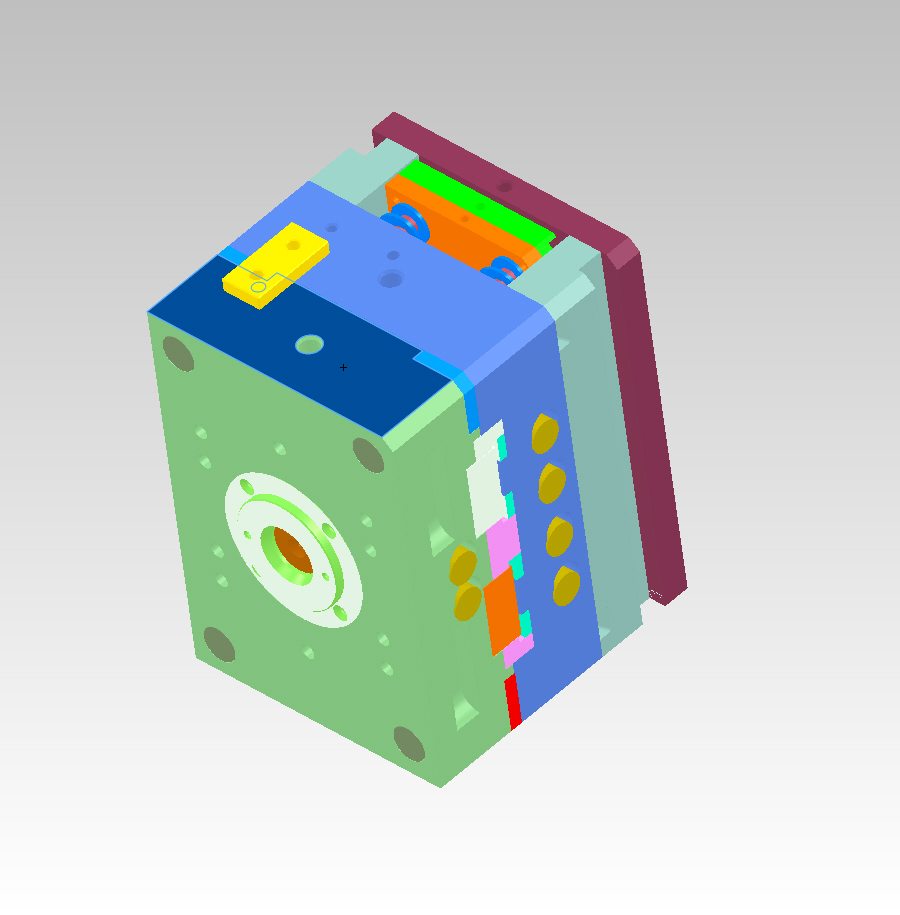

Tooling

First, we ask questions to learn short-term needs and the long-term goals of the project. We review the Part Design, Material Selection and Lead Time Requirements. Based on our findings we develop a quote using J&L’s resources.

What type of Framing System?

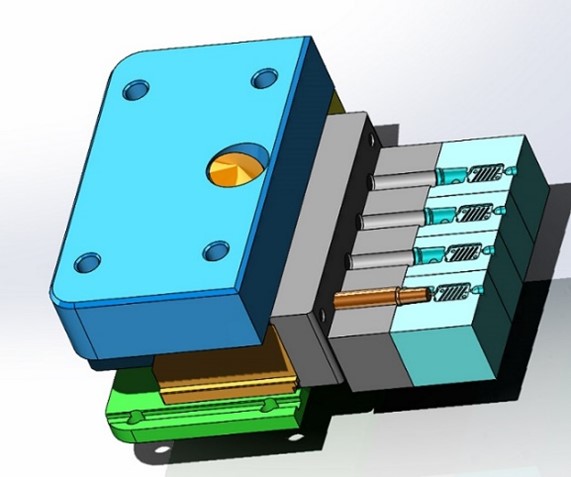

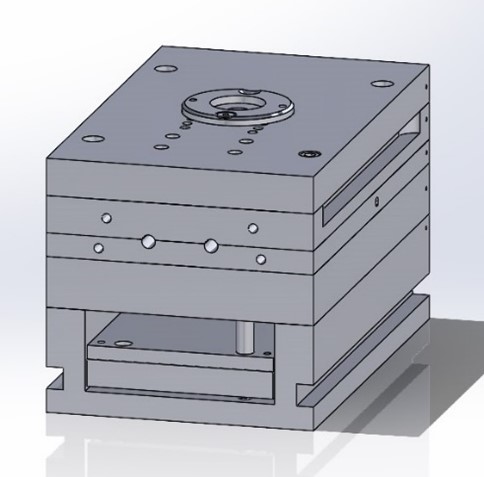

Based on the specifications of the project J&L will choose the proper Frame System:- Master Unit Die (MUD) Frame System allowing the Customers to only purchase the insert mold (cavity). It is not necessary to purchase an entire standard mold frame. Saves time and money.

- Prototype Plus Frame System developed by J&L Plastic Molding using S-7 steel cavity blocks to fit a standard frame. This standardized system saves time and money with the advantage of meeting production capacity.

- DME Mold Base: Conventional mold base and cavity blocks.

Does J&L build steel or aluminum tools?

J&L builds steel tools based on these factors:- Hardness: The hardness of steel is required for parts with complex geometry, thin walls and tolerance concerns.

- Molding Pressures: Steel tools hold up to the pressure of the molding process. Steel tools have less risk of developing quality issues such as Flash.

- Longer Tool Life: Steel tools have longer tool life and provide savings on maintenance and replacement costs.

- High Heat Materials: Tools made from steel are necessary to process high heat materials such as ULTEM and PEEK.

- Abrasive Materials: Steel tools hold up when processing abrasive materials with glass filler and other additives.

J&L has complete Tooling capabilities in our facility. We build and maintain Tools.

Designing and building the proper tool is the just the beginning of the relationship with J&L.

Injection Molding

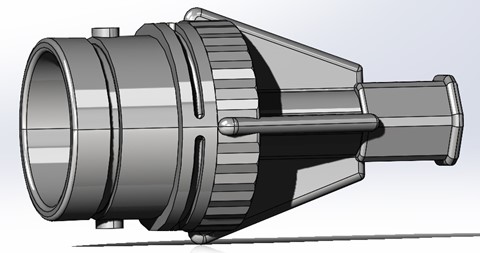

Operating in two buildings in Wallingford, Connecticut, J&L Plastic Molding has 28 injection molding machines ranging from 28 to 385 tons of clamp force, and shot sizes from .6 to 24 ounces. We are proficient at production injection molding, prototype molding, Overmolding, and Insert Molding. We process the full range of performance materials from commodity grades to engineering thermoplastic resins.

Capabilities supporting our Injection Molding Operation

- Machining: J&L can machine part features as a post-molding operation. We can also machine Plastic, Stainless Steel, Aluminum and Brass parts.

- Ultrasonic Welding: The application of high-frequency vibrations to two parts by a vibrating tool, known as a “horn.” Welding occurs as the result of heat generated at the interface between the parts or surfaces. It’s fast and efficient.

- Pad Printing / Plastics Decorating: Pad printing is an offset process. An engraved plate is coated with ink, then squeegeed, leaving wet ink on the plate in the engraved pattern. A silicone pad is pressed onto the plate and rises with the inked image. The inked pad descends onto the plastic component and imprints the image. Because the pad is pliable, it can form around irregular surfaces.

Engineering Grade Material Processed at J&L – click below to view parts

Quality

J&L Plastic Molding’s management system has been certified to ISO 13485:2016 standard.

Customer Service

J&L’s customer service is based on supporting our Customers’ plastic injection molding needs by being on-time with the Quality required. We are set up to service your business with ERP and Manufacturing Software. We utilize the Shoptech Software System – E2 to seamlessly perform the following tasks:

- Process Purchase Orders

- Schedule Orders

- Retain vital information

- Maintain Quality Control

- Streamline Shipping & Invoicing

As a result, J&L will is a low maintenance Supplier. Low on problems, high on solutions.

Where We Came From

J&L Plastic Molding was founded in 1972 as a prototype tooling and injection molding company. Today, with decades of experience behind us, J&L has grown to service the development and production needs of FORTUNE 500 original equipment manufacturers, start-up medical device manufacturers and companies in diverse industries.