Polycarbonate Injection Molding Parts Processed at J&L

Polycarbonate – Robust and Versatile

Polycarbonate is an amorphous engineering thermoplastic with a high level of mechanical, optical, electrical and thermal properties. It offers outstanding mechanical, clarity, electrical and thermal properties. PC allows for design versatility. Different options include scratch resistance, toughness, heat resistance, weatherability, biocompatibility and compliance with FDA and USP requirements. Additives allow PC to be flame retardant. J&L Plastic Molding will help you realize these benefits:

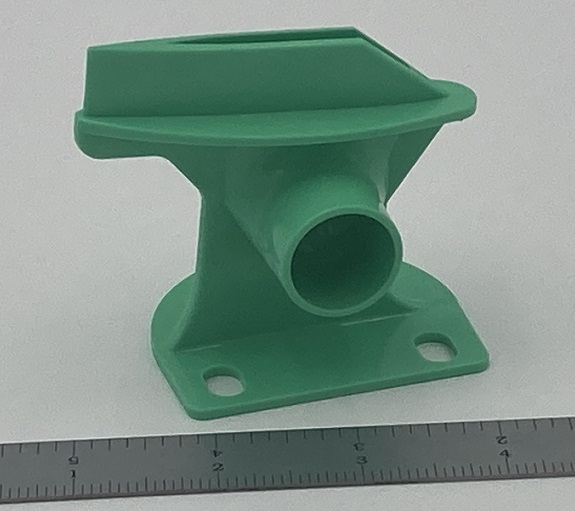

Excellent Mechanical Properties

Polycarbonate Injection Molding parts exhibit exceptional impact resistance. PC is ideal for parts subject to high-stress environments or impacts. Its strength and toughness ensure longevity and durability.

High Temperature Resistance

Polycarbonate withstands a range of high temperature without deformation or loss of mechanical properties.

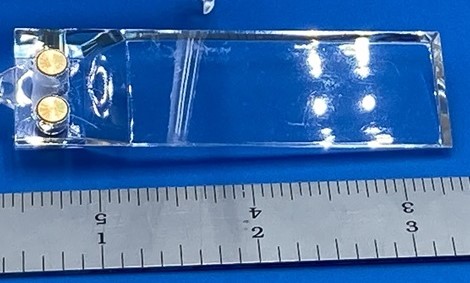

Transparency and Clarity

Polycarbonate possesses excellent transparency. It is an excellent choice for applications requiring clarity and cosmetic appearance.

Dimensional Stability

Polycarbonate exhibits minimal shrinkage. Its shrink value is from 0.005” to 0.007”. It produces consistent parts with excellent dimensional stability. PC can hold tight tolerances and can be processed into intricate shapes with complex geometry.

Chemical resistance

Polycarbonate demonstrates good resistance to many chemicals, including oils, greases, and various solvents.

Medical Device Grades Available

CLICK HERE to learn more about our Medical Device Injection Molding expertise.