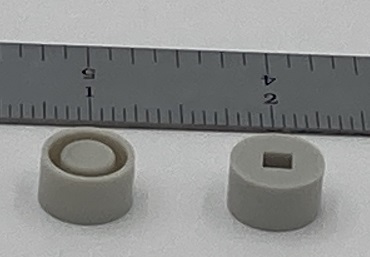

ABS Injection Molding Parts processed at J&L

ABS Advantages – Tough, Cosmetic and Stable Dimensions

ABS Injection Molding parts offer several advantages. It is trusted for mechanical properties, processability, and overall performance. J&L Plastic Molding will you realize the following benefits:

Strength and Stiffness

ABS exhibits good mechanical strength and stiffness. It has high tensile strength. ABS parts offer excellent impact resistance.

Dimensional Stability

ABS possesses good dimensional stability and will maintain its shape and size under changing temperature and humidity conditions. ABS’ shrink value is from 0.004” to 0.008”. Its stable shrink produces consistent parts.

Chemical Resistance

ABS has good resistance to a wide range of chemicals, including acids, alkalis, oils, and various solvents.

Surface Finish and Decorating

ABS parts can achieve a high and low gloss surface finish. It is excellent with post-processing techniques such as painting, printing, and plating. ABS offers superior surface quality and brilliance.

Medical Device Grades Available

CLICK HERE to learn more about our Medical Device Injection Molding expertise.

Links to ABS Material Suppliers:

ABS Sterilization Methods

ABS is increasingly being used in medical devices due to its processability, cosmetic look, ability to be colored and toughness. Here is a rundown of ABS’ compatibility with sterilization methods.

Note: Sterilization information is for reference only. Sterilization methods must be determined during product development.

- Gamma Sterilization compatibility: Good

- Ethylene Oxide (EtO) compatibility: Good

- Electron Beam compatibility: Good

- Autoclave compatibility: Poor