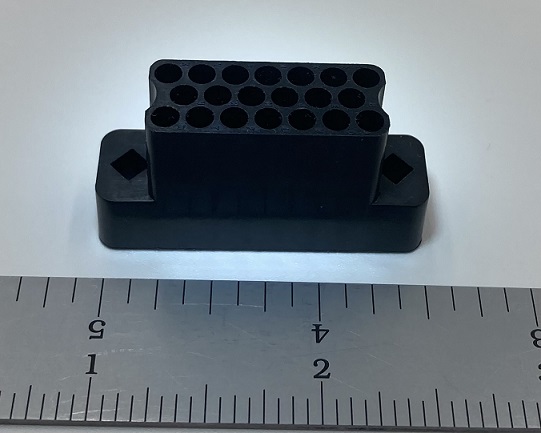

PBT Injection Molding Parts Processed at J&L

Polybutylene Terephthalate (PBT) is an engineering grade material with high strength, rigidity and toughness. It offers the following properties and specifications:

Excellent Mechanical Properties

PBT injection molding parts are hard, rigid and strong. It’s suitable for injection molding parts subject to mechanical stress.

Dimensional Stability

PBT injection molding parts have excellent dimensional stability due to low thermal expansion coefficient and low water absorption. It works well in tight-tolerance applications.

Chemical Resistance

PBT demonstrates good resistance against a wide range of chemicals, including acids, bases, alcohols, and hydrocarbons.

Flame Retardancy

Many PBT grades are inherently flame retardant and meet UL Flammability standards.

Heat Resistance

PBT will withstand continuous use at elevated temperatures to 140°C (284°F). It will maintain mechanical properties at higher temperatures.

Weathering and UV Resistance

PBT has good weathering resistance. UV stabilizers will enhance its resistance to degradation when exposed to sunlight or UV radiation.

Low-Friction and Wear-Resistant Properties

PBT has excellent surface hardness and scratch resistance. PBT injection molding parts will withstand wear or friction.

PBT Use in Medical Equipment

PBT provides exceptional chemical resistance to withstand strong disinfectants being adopted to combat healthcare facility-borne infections. For portable medical equipment it offers high impact resistance and dimensional stability to withstand bumps and bangs during transport within a healthcare facility. Flame-retardant and ultraviolet-stabilized PBT offers outstanding aesthetics and provides molded-in color as an alternative to traditional painted metal. PBT delivers the processability required for molding high-quality, precision parts.

CLICK HERE to learn details on J&L’s medical device molding expertise

.