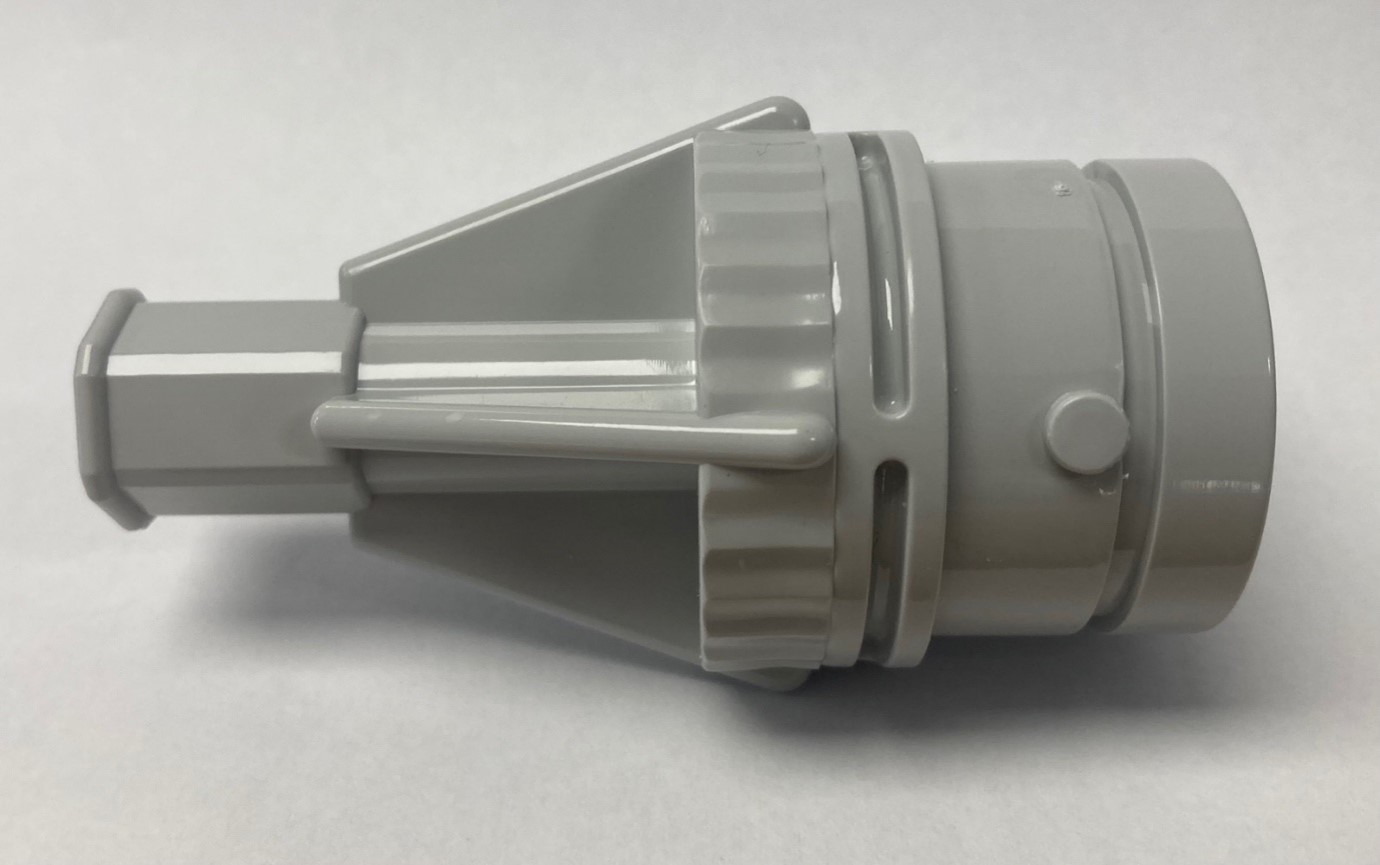

Vascular Medical Molding Case Study

A new Adapter was required by a leading global medical device manufacturer for the treatment of peripheral vascular disease. J&L was contacted to provide a Medical Molding solution.

The Specs of the Adapter Medical Molding Project

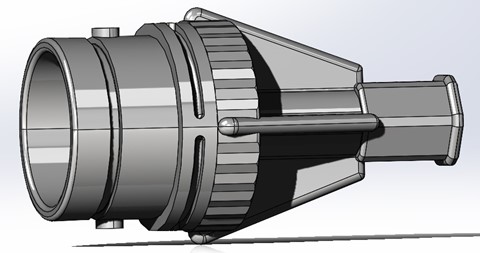

The challenge for this injection molding project was to design and build Tooling to injection mold the Adapter to specifications and budget.

Part Specifications

| Material Spec | ISO 10993/UPS Class VI Compliant |

| Polymer Material | ABS Lustran 348 |

| Tolerance | +/-.002 several dimensions |

| Finish | SPI A2 |

CLICK HERE to learn more about J&L’s Medical Device Injection Molding expertise.

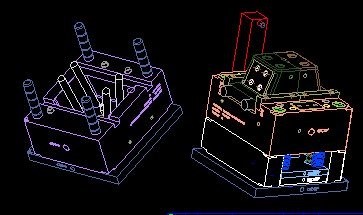

Tooling

J&L Plastic Molding sourced the tooling from our Vendor. The Vendor completed the Tooling Work and initial sampling. The Tool was shipped to J&L’s Connecticut facility for production. Tool Maintenance will be handled by J&L’s in-house Toolroom.

Tool Design: Our Tooling Vendor designed the Tool. J&L approved the 3D CAD Design of the Tool prior to machining.

Tool Sampling: To prepare for the sampling of the tool J&L shipped the ABS Material to the Tooling Vendor for the sampling process. The Tooling Samples were submitted to and approved by J&L.

Sampling at J&L & Pad Printing: The Tooling arrived at J&L’s facility and was sampled. J&L submitted the injection molded samples to our healthcare customer and was approved for Production.