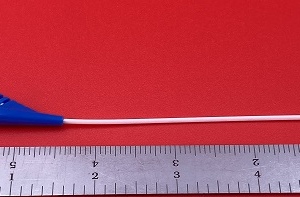

TPU Injection Molding Parts processed at J&L

TPU Injection Molding – Versatile and Adaptable

TPU provides a high degree of flexibility and resistance across a wide range of temperatures. It is available in a wide range of durometers from hard and stiff to soft and elastic. TPU is ideal for a wide range of industrial and consumer applications. Its adaptability can combine the contrasting features of rubber and plastics in terms of flexibility and rigidity. J&L will help you realize these advantages:

Versatility

TPU offers a wide range of properties making it suitable for diverse applications. It exhibits excellent mechanical strength, toughness, and abrasion resistance, allowing it to withstand demanding operating conditions.

Flexibility and Elasticity

TPU has outstanding flexibility and elasticity. It can be easily stretched and bent without permanent deformation. It shows good resilience and will endure repeated cycles of stress or strain.

Chemical Resistance

TPU provides resistance to various chemicals, including oils, greases, solvents, and fuels. Parts processed from TPU maintain their integrity and performance even in contact with potentially corrosive substances.

Wide Durometer Range

TPU materials are available in a broad range of hardness levels. Parts processed from TPU range from very soft and rubber-like to rigid and semi-rigid. It allows engineers to balance flexibility, durability, and stiffness.

Excellent Wear and Tear Resistance

TPU Injection Molded parts have exceptional wear resistance properties. Its suitable for parts that experience friction, abrasion, or impact. TPU is outstanding for seals, gaskets, belts, wheels and other parts subjected to constant contact or repetitive motion.

UV Stability

Many TPUs exhibit good resistance to ultraviolet (UV) radiation. It is often specified for applications requiring prolonged exposure to sunlight or outdoor environments.

Links to TPU Material Suppliers: