Medical Device Molding Case Study

SCOPE: A Medical Device company that designs, manufactures and markets medical instruments required a high performing Sheath Tip as part of an assembly. They contacted J&L Plastic Molding for a Medical Device Molding solution.

The Challenge & Specs of the Sheath Tip Medical Device Molding Project

The challenge for this project was to design and build Tooling to injection mold the Sheath Tip to the customer’s specifications and budget.

Part Specifications

| Material & Artwork Spec | ISO 109993/UPS Class VI Compliant |

| Polymer Material | PPSU – Radel |

| Tolerance | +/-.002 several dimensions |

| Finish | SPI B2 |

Tooling

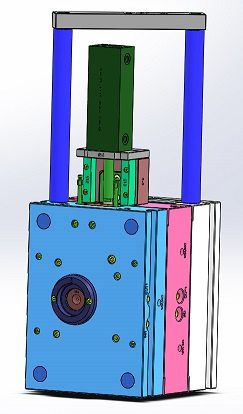

The Tooling was sourced to J&L Plastic Molding’s Tooling Vendor. J&L Plastic Molding has had years of experience and many successful medical device tooling projects with the Vendor. The Tooling Work and initial sampling were to be completed by the Vendor. The Tool was shipped to J&L’s facility for production. J&L’s in-house Toolroom will handle all Tool Maintenance.

Tool Design: The Tool was designed by the Tooling Vendor. The Designed was submitted to J&L and approved prior to machining.

Tool Sampling: To prepare for the sampling of the tool J&L shipped the PPSU Material to our Vendor for the sampling process. After the toolmaking process was complete (8 Weeks) the Tooling Samples were submitted to J&L and approved.

Sampling at J&L & Pad Printing: The Tooling arrived at J&L’s facility and was sampled. J&L completed the Pad Printing to the Customer’s specification and the Sheath Tip was approved for Production.