Use of Automation in Injection Molding Case Study

A manufacturer of Portable Test Kits and Instruments to detect and quantify contaminants in soil, water and oil required a new Breakaway Cap for use in the field. To find a find a solution J&L Plastic Molding developed automation to improve the injection molding process.

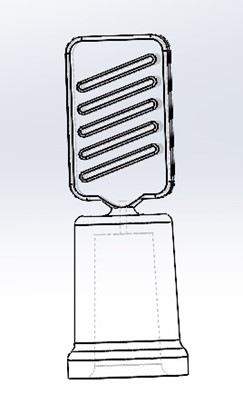

The Breakaway Cap Project

The challenge for this injection molding project was to design and build Tooling to process, eject and de-gate the Breakaway Cap.

Part Specifications

| Material Spec | Polypropylene |

| Polymer Material | Pro-Fax 6323 |

Click Here to Request a Quote!

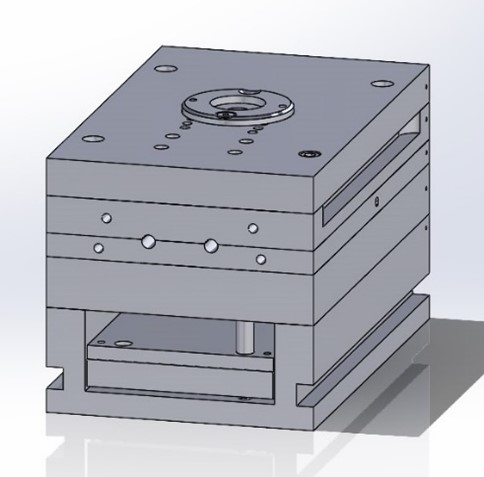

Domestic Tooling – developing automation in Injection Molding

The Tool was made in Connecticut. The Tooling Approval and Sampling were completed at J&L. J&L’s in-house Toolroom will handle all Tool Maintenance.

Tool Specifications

| # Cavities | 4 Cavity Mold |

| Tool Material | Hardened H13 Cavity and Core |

| Mold Base | DME style frame |

| Gating | Hot Tip |

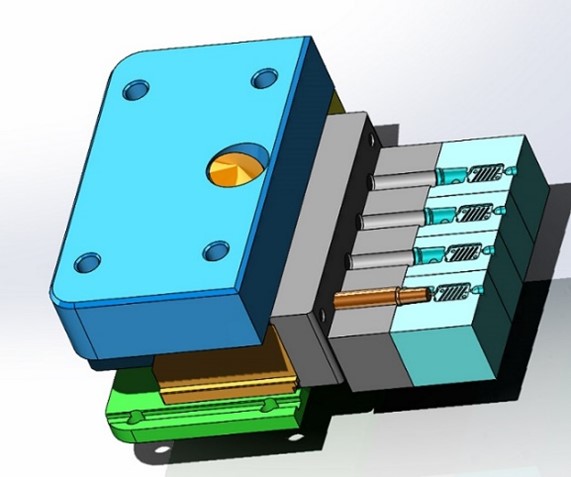

De-Gating

To De-Gate the parts from the runner system, J&L uses end-of-arm robotics to pick the runner system and parts from the mold. The end-of-arm robotics then positions the runner system and parts to a cutting fixture to separate the parts from the runner system.

See the De-Gating Video!